38 electrical panel labeling standards

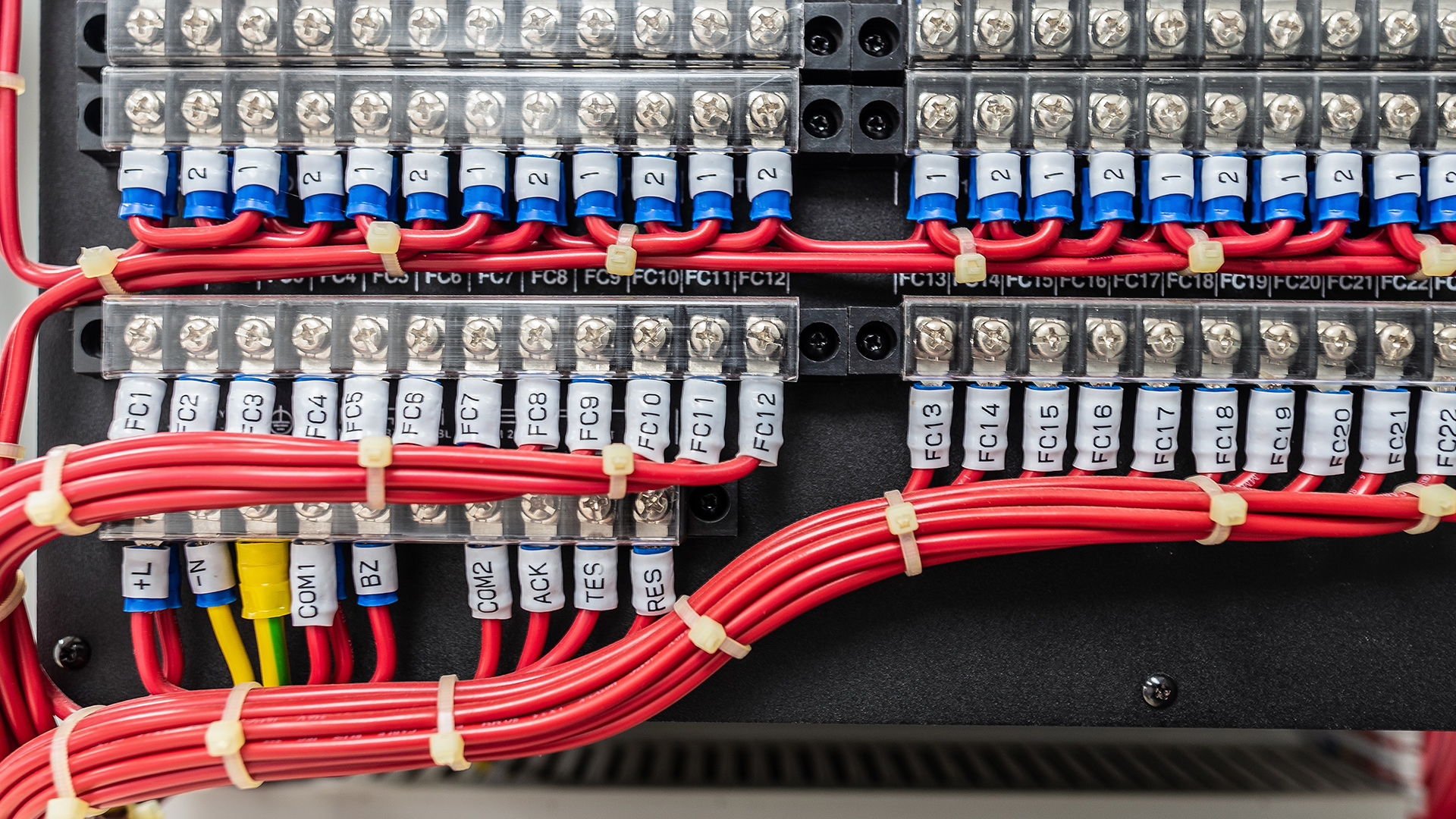

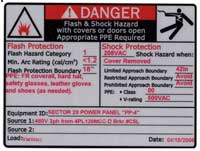

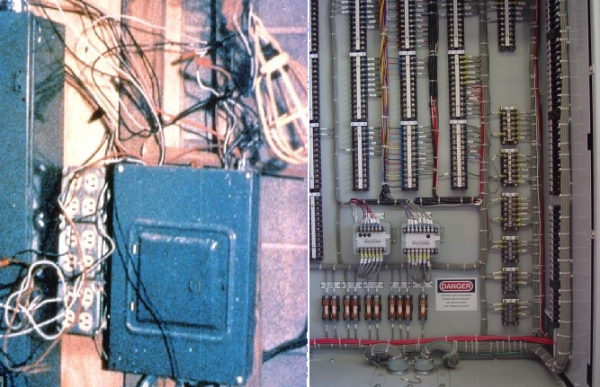

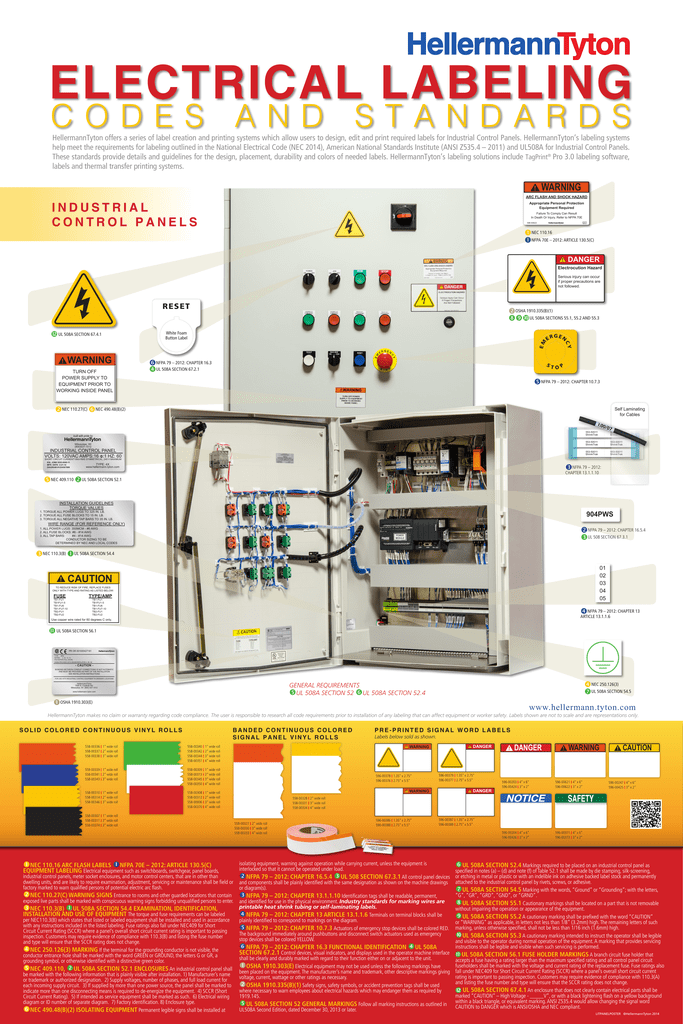

Strategies for electrical labeling and documentation Why electrical equipment must be labeled. Strategies for labeling and documentation are partially driven by applicable code requirements. An obvious location to look for requirements is NFPA 70E-2015: Standard for Electrical Safety in the Workplace, Article 130.5(C)(2)(D). This section specifies the type of labeling information required and includes available incident energy and personal protective equipment (PPE) categories. In addition, Sec. 16.5.4 of this same standard states, "all control panel devices shall be plainly identified with the same designations as shown on the machine drawings or diagrams" ( Photo 3 and Photo 4 ). Even the emergency stop label defined in Sec. 10.7.3 is required to be yellow ( Photo 5 ). Photo 5.

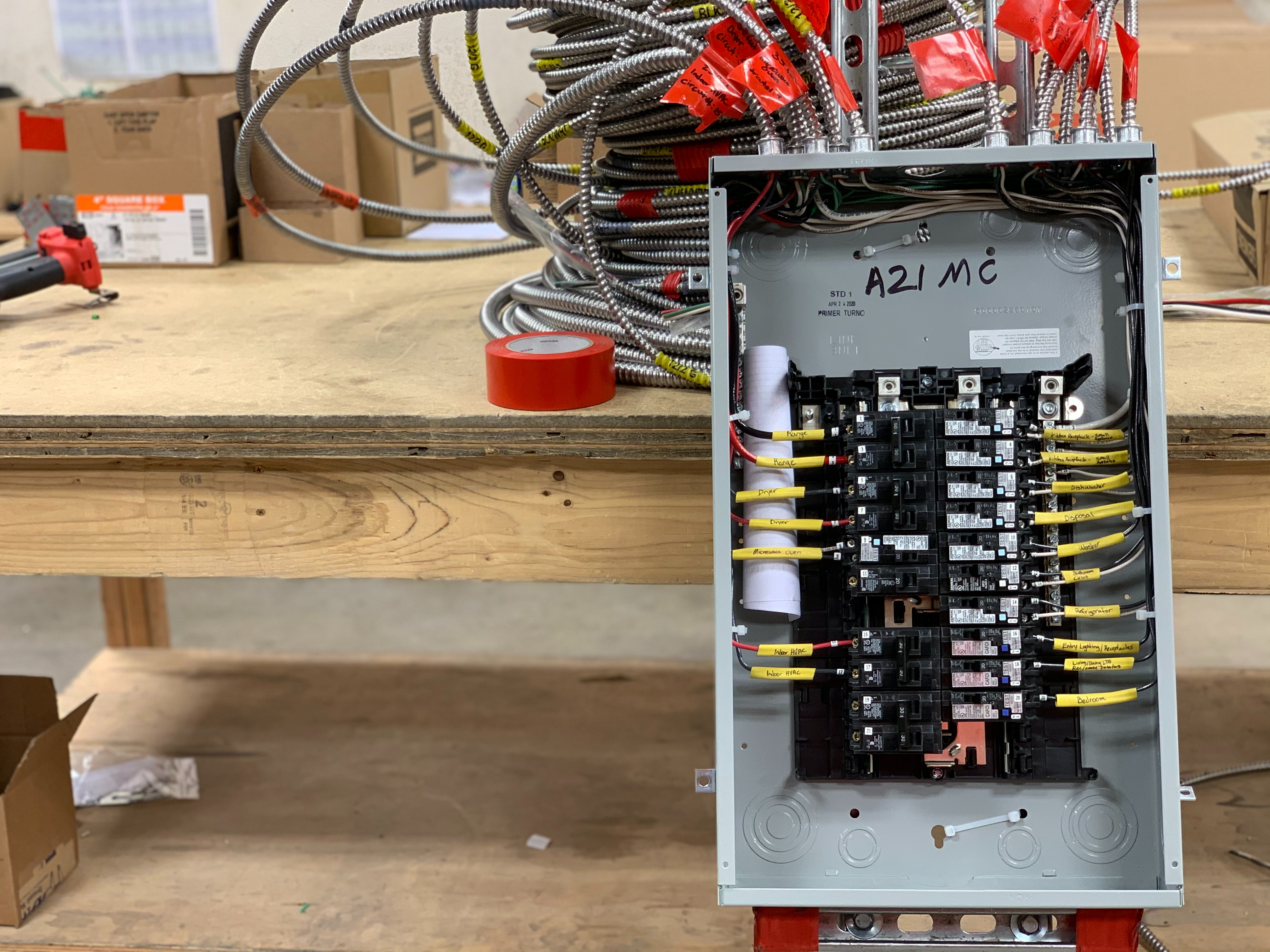

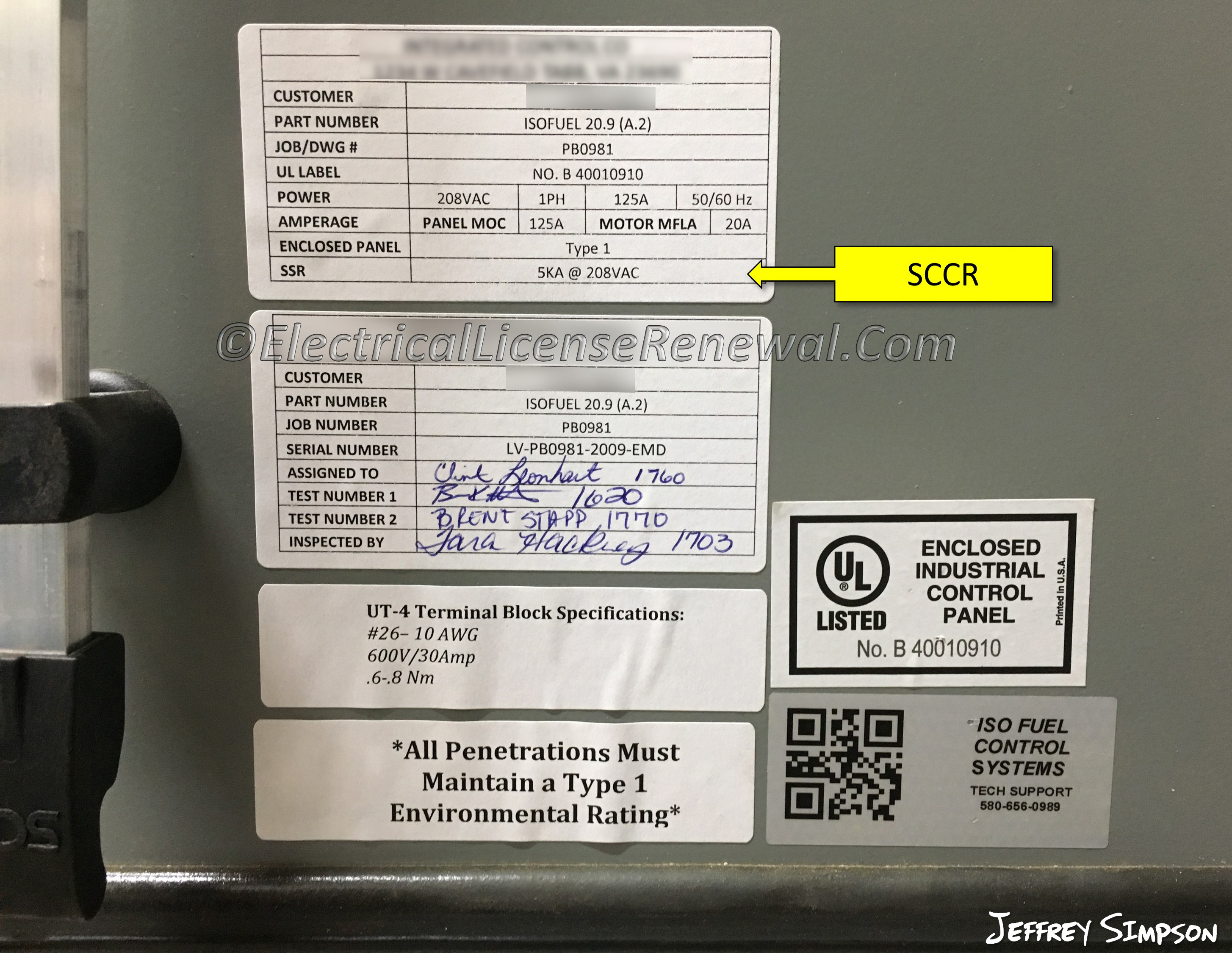

May 15, 2013 · This panel shows all the appropriate labeling as required by the NEC and NFPA 70E, per ANSI Z535 label design formats. Note how the phases are marked in this example. Most facilities have a transfer switch that is designed to sense a loss of power and then transfer from the electric utility feed to an on-site generator feed to re-energize a ...

Electrical panel labeling standards

Electrical - Standards - Occupational Safety and Health Administration Standards Electrical is addressed in specific standards for general industry and maritime. This section highlights various OSHA standards and documents related to electrical hazards. OSHA Standards Visit the Electric Power Generation, Transmission and Distribution Standard Page for information on the final rule. State Standards OCWR - Electrical Panel Safety For equipment operating at 600 volts, nominal or less to ground, electrical panels must have a minimum of three feet of clearance in front of the panel and a minimum clearance width of 2.5 feet or the width of the equipment, whichever is greater. NEC 110 Labeling Requirements | Graphic Products Labels are required to be field installed on new equipment The information on the labels must be checked when changes are made Some facilities are exempt from these requirements The first requirement is that labels showing the maximum available fault current be field installed. NEC 110.24 states: Field Marking.

Electrical panel labeling standards. Everything You Need to Know About Electrical Panel Labels (2022) There are thousands of ANSI standards, but the one most important for electrical panel labeling is ANSI Z535 and specifically ANSI Z535.4 American National Standard for Product Safety Signs and Labels. See Also ANSI Z535.4 4.11: "A symbol that indicates a hazard. It is comprised of an equilateral triangle surrounding an exclamation mark. PDF Electrical Electrical Identification Basis of Design Label conduit at all wall penetrations and connections to all panels, junction boxes, and equipment served. 3. Use a black indelible marker and hand print label in a clear workmanlike manner, or use stencil and black paint to provide a clearly legible label. C. Empty conduits 1. PDF Electrical Panel and Circuits, Marking - ResponsibleAg 29 CFR 1910.303(e) - Electric equipment may not be used unless the following markings have been placed on the equipment: 1. The manufacturer's name, trademark or other desc riptive marking by which the organization responsible for the product may be identified; and 2. Other markings giving voltage, current, wattage or other ratings as necessary. Labeling Services | Identification Products | Marking ... We deliver a comprehensive range of superior labeling products and services to facility owners and construction contractors for enhanced communications, operability and safety. View Products We manufacture a full variety of exceptional labeling and identification products to serve multiple industries.

2022 Electrical Panel Upgrade Cost | Cost to Replace an ... Feb 11, 2022 · The cost to relocate an electrical panel starts at around $1,000 but can go as high as $4,000 if a lot of rewiring must be done to accommodate the move. Cost to Rewire an Electrical Panel . Homeowners may not have much insight into whether the wiring of an electrical panel is in poor condition. Wiring Color Codes - NEC Electrical Standards & 3-Phase It’s safe. And, it’s designed to take the guesswork out of electrical work. But it wasn’t always this way. A brief history of wiring color codes. It took until 1928 for wire color coding to make its debut. The National Electrical Code® (NEC) was the first to reference it, and today continues to set the standards for the electrical industry. Do I Need to Label My Electrical Panel? - Piper Electric The first step you should take while labeling your electrical panel is turning off all circuit breakers. Then, see which appliance or fixture turns on when you turn on the breakers one by one. You can also check the power outlets by plugging in an alarm clock or lamp or using a voltage tester. Now, the entire process may take some time; however ... Join LiveJournal Password requirements: 6 to 30 characters long; ASCII characters only (characters found on a standard US keyboard); must contain at least 4 different symbols;

Electrical panel labeling requirements osha Exterior electrical panels have a door that latches at the bottom. Often, homeowners will padlock these panels closed to prevent intruders from accessing the breakers or main disconnect and cutting power to the house. A padlocked electrical panel is a safety issue that can prevent access to the electric breakers in an emergency. What are the Requirements for Labeling Circuit Breakers? Electrical Panel Labeling Guide: Stay safe. Stay compliant. When it comes to powering your facility, there's nothing more essential than electrical panels. For safety and OSHA compliance, it's important that your panels are easy to find and clearly labeled. This instructive guide gives you tips and tricks for smart and safe panel labeling. Complete Guide to Electrical Panel Labels - Metalphoto Of Cincinnati There are thousands of ANSI standards, but the one most important for electrical panel labeling is ANSI Z535 and specifically ANSI Z535.4 American National Standard for Product Safety Signs and Labels. ANSI Z535.4 4.11: "A symbol that indicates a hazard. It is comprised of an equilateral triangle surrounding an exclamation mark. Electrical Panel Location and Installation: Clearance, Bathrooms ... Electrical panels need to be installed 4′ off the ground with the center grip handle of the highest circuit breaker is no more than 6'7″ high to be NEC compliant. The clearance around the electric panel must be at least 30 inches wide with 3′ of front workspace clearance. The electric panel door must be able to open to a 90-degree angle.

What are the Requirements for Electrical Panel Labeling? In general, the three most important places to look for electrical panel labeling requirements are the National Fire Protection Association (NFPA), the American National Standards Institute (ANSI), and the Occupational Safety and Health Administration (OSHA). Of course, you will also want to reference any local agencies that may have specific requirements for your area.

Electrical Safety Questions and Answers - Creative Safety Supply Taking Electrical Safety Seriously. We have written a series of common questions and answers related to electrical safety to help companies keep their employees and facilities safe. These posts are written for anyone in the workplace that is responsible for facility safety in general, and electrical safety specifically.

Step by Step Guide to Labeling Your Electrical Panel — Multi Trade ... The simplest reason to label your electrical panel is that it is an Ontario Electrical Code requirement. The Electrical Safety Authority sets out a clear set of rules and policies to ensure the safety of the public. One of those rules is to have your electrical panel appropriately labeled. What you need to do this yourself

42 Fillable Panel Schedule Templates (Excel & Word) Appropriate labeling standards are as important, allowing you to identify apparatus that has to be de-powered even when there are several breakers controlling identical machinery and when there is personnel in the facility who are not familiar with the infrastructure. ... Types of electrical panel schedule templates. There are three main types ...

Electrical panel labeling requirements osha - hdd.jackland.shop Electrical panel clearance requirements . 02/02/2004. Exposure to light ... 12/14/2017. Labeling field requirements . 08/24/1998. Labeling of temporary electrical circuits. 04/01/1993. Neutral conductor - required clearances . 08/15 ... To provide inspection guidelines relating to OR- OSHA 's rules addressing work practices and procedures. ...

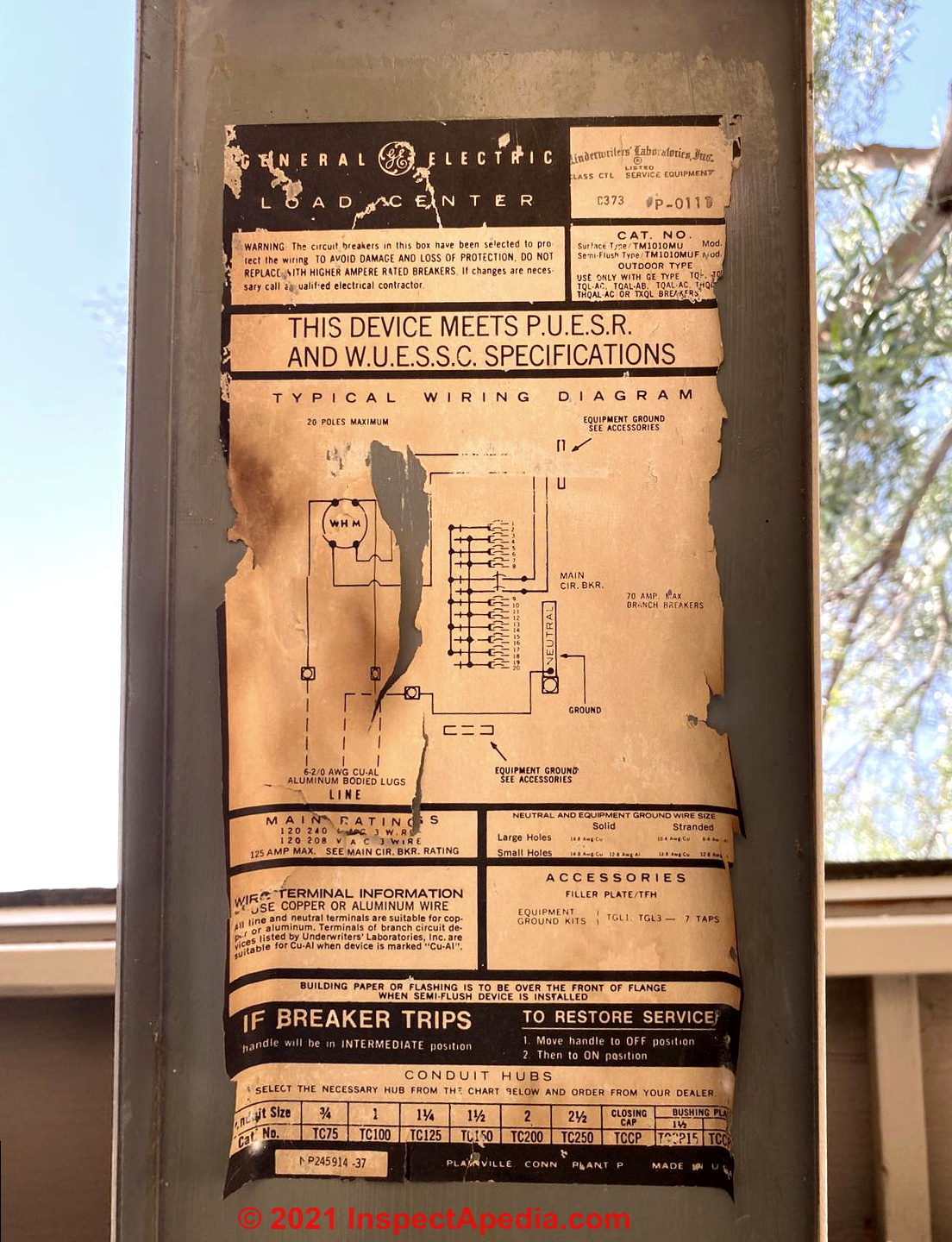

Service Equipment Labeling — NEC 2017 110.16(B) - IAEI Magazine The contents of the label will depend upon which method is used to satisfy this requirement found in 110.16 (B). The label as required in the parent text of 110.16 (B) must adhere to 110.21 (B) and include the following information: Nominal system voltage Available fault current at the service overcurrent protective devices

Electrical Panel Labels and Nameplates • OEM Panels The label to the right shows the benefits of using a Multi-Color Graphic Door Laminate. One label includes the customer's corporate identity, operator device functionality, safety labels, and a Made in America label. 2 • Engraved Plastic Tags. Most panel builders make engraved plastic tags because they were the standard for twenty years.

1910.303 - Occupational Safety and Health Administration Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling. 1910.303 (b) (3) Insulation integrity . Completed wiring installations shall be free from short circuits and from grounds other than those required or permitted by this subpart. 1910.303 (b) (4) Interrupting rating .

Arc Flash Labeling Requirements | Comply with 2021 NFPA 70E The National Fire Protection Association (NFPA) details how to comply with the Occupational Safety and Health Administration's (OSHA) regulation, 29 CFR 1910.333(a), through the NFPA 70E standard. Applying these electrical safety standards in the workplace protects workers who may be exposed to arc flash or other electrical hazards.

NFPA 70E minimum labeling for panels | Electrician Talk Article 130.5 (C) Equipment Labeling. Electrical equipment such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers that are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked with a label containing all the following information:

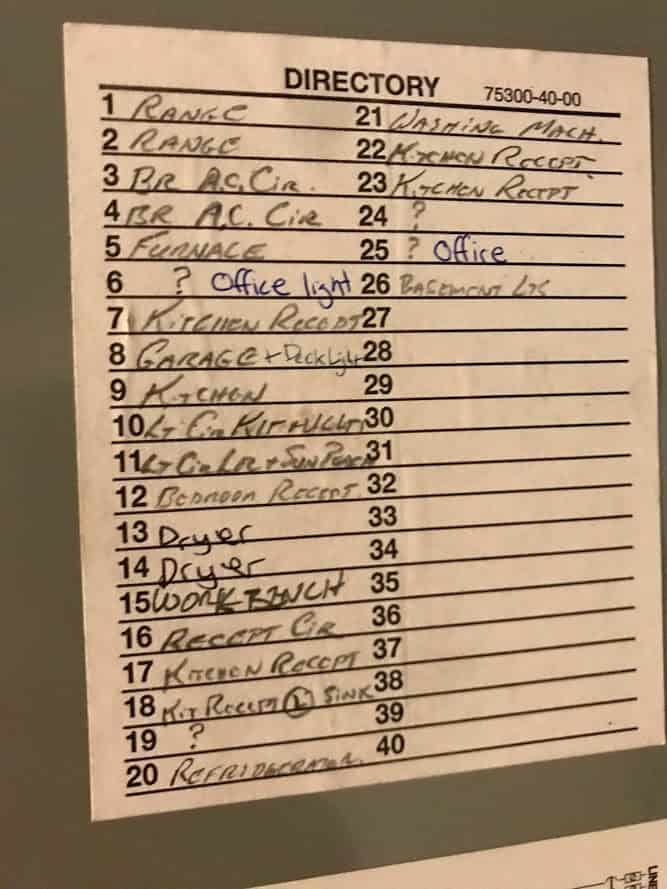

Electrical Panel Labels | Family Handyman The identification must be included in a circuit directory that is located on the face or inside of the panel door. The circuit directory must be durable enough to withstand the environment in which it is located. Each label identification must contain a degree of detail that distinguishes it from all other circuits.

How To Label An Electrical Panel (The Right Way) in Your Tigard Oregon Home Fill in each line that is used. Do not use the exact same description for more than one circuit. Do not use terms specific to your house to describe the circuits. It is best to label them specifically, such as southwest bedroom; upstairs north bedroom; basement west bedroom; etc. instead of bedrooms 1, 2, and 3.

NEC + OSHA Electrical Panel Clearance Requirements In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36'' of clearance around it. Panels with 151 to 600 volts should have 42'' of clearance around it. This NEC working clearance will provide not only the person working on the equipment with room, but also their tools.

Industrial Control Panel Design Guide: Schematics, Standards, Design ... The process should always begin with an evaluation of the specifications, requirements, and regulatory standards. After these considerations are evaluated, drawings are created to outline the specific configuration of wiring, circuits, controls, and every other aspect of the final control panel. Good design addresses both the electrical and physical requirements.

How to Label an Electrical Service Panel | Hunker Step 1: Number Each Circuit Breaker. Assign each circuit breaker a number inside the panel, starting with #1 at the top left. It's best if the number sequence proceeds down the left side to the bottom and continues from the top right to the bottom right. Write each number with a felt tip marker on a 1-inch square sticky label and affix each ...

NEC 110 Labeling Requirements | Graphic Products Labels are required to be field installed on new equipment The information on the labels must be checked when changes are made Some facilities are exempt from these requirements The first requirement is that labels showing the maximum available fault current be field installed. NEC 110.24 states: Field Marking.

OCWR - Electrical Panel Safety For equipment operating at 600 volts, nominal or less to ground, electrical panels must have a minimum of three feet of clearance in front of the panel and a minimum clearance width of 2.5 feet or the width of the equipment, whichever is greater.

Electrical - Standards - Occupational Safety and Health Administration Standards Electrical is addressed in specific standards for general industry and maritime. This section highlights various OSHA standards and documents related to electrical hazards. OSHA Standards Visit the Electric Power Generation, Transmission and Distribution Standard Page for information on the final rule. State Standards

/residential-circuit-breaker-panel-with-service-writing-184303809-5841f5ab5f9b5851e5701860.jpg)

Post a Comment for "38 electrical panel labeling standards"