38 electrical panel label requirements

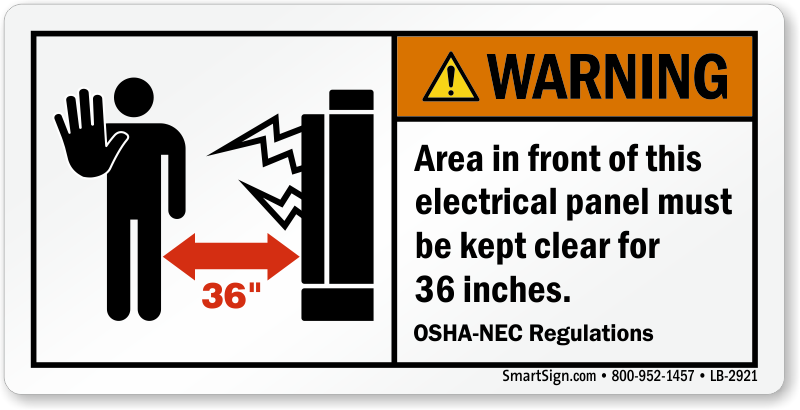

A simple label attached to the front of the panel is all that is required. The 120V system is usually wired in black, red, and blue while the 277V version is wired in brown, orange, and yellow. While a 120V system is usually wired in black, if you have a 120/240V delta with a high leg, then the phases end up being in black, orange, or blue. Electrical Panel Location and Installation: Clearance, Bathrooms ... Electrical panels need to be installed 4′ off the ground with the center grip handle of the highest circuit breaker is no more than 6'7″ high to be NEC compliant. The clearance around the electric panel must be at least 30 inches wide with 3′ of front workspace clearance. The electric panel door must be able to open to a 90-degree angle.

Arc Flash Labeling Requirements | Comply with 2021 NFPA 70E According to NFPA 70E, labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized. These labels communicate the electrical hazards an employee may be exposed to, including the potential for an arc flash incident.

Electrical panel label requirements

Electrical Panel Compliance with Floor Marking - Graphic Products The width of the space in front of an electrical panel must be the width of the equipment or 30 inches, whichever is wider. The working space must allow for a hinged panel or equipment door to open at a 90° angle. The vertical space must extend from the grade, floor, or platform immediately in front of the electrical panel to either: Required Labels On Electrical Panels - Nfpa Electrical Panel Labeling ... The electrical code requires you to label, or index, your panel. All labels and markings must be durable enough to withstand weather, chemicals,. Basic electricians pouch hand tools, voltage tester, and appropriate safety gear. Even if you don't plan on selling your home any time soon, it's still a good safety practice. Electrical Panel Labels | Family Handyman The identification must be included in a circuit directory that is located on the face or inside of the panel door. The circuit directory must be durable enough to withstand the environment in which it is located. Each label identification must contain a degree of detail that distinguishes it from all other circuits.

Electrical panel label requirements. How To Label An Electrical Panel (The Right Way) in Your Tigard Oregon Home Follow these steps to make sure your panel is labeled correctly: Each circuit needs to be specifically identified. Do not use abbreviations or symbols to describe what is on each circuit. Fill in each line that is used. Do not use the exact same description for more than one circuit. Do not use terms specific to your house to describe the circuits. Strategies for electrical labeling and documentation Any panel or piece of equipment should have a label to identify where power can be disconnected (see Figure 2). Lockout-tagout procedures should be considered when deciding labeling details. Equipment labeling may include voltage, source-panel name, and source-panel location (if elsewhere in the facility). Service Equipment Labeling — NEC 2017 110.16(B) - IAEI Magazine Figure 1. Arc flash hazard warning label as required by 110.16 (A) of NEC 2017. NEC 2017 introduced the new first level subdivision 110.16 (B) Service Equipment. This new addition applies only to service equipment rated 1200 amps or more. Note that this is the rating of the equipment, not the rating of the OCPD protecting the service equipment. 1910.303 - Occupational Safety and Health Administration 1910.303 (g) (1) (vii) (A) (2) The space equal to the width and depth of the equipment shall be kept clear of foreign systems unless protection is provided to avoid damage from condensation, leaks, or breaks in such foreign systems. This area shall extend from the top of the electric equipment to the structural ceiling;

Do I Need to Label My Electrical Panel? - Piper Electric Co., Inc. Piper Electric's COVID-19 Safety Requirements; CONTACT (303) 422-9219; Previous Next. View Larger Image. Do I Need to Label My Electrical Panel? ... Lastly, if you are facing any trouble while labeling your electrical panel, you should consider taking the help of a professional. Electrical panel labeling is not easy. › electrical-service-panelsElectrical Service Panels - InterNACHI® panel manufactured by Zinsco or Federal Pacific Electric (FPE). These panels have a reputation for being problematic and further evaluation by a qualified electrician is recommended. Zinsco panels can generally be identified by a blue and silver "Zinsco" label inside the panel, and an embossed "Magnetrip" label at the top of the panel face. NEC 408.4 (A) panel requirements - Mike Holt's Forum The contractor is insisting that the distribution panels do not require proper labeling of any form as outlined in NEC 408.4 (A). They are maintaining that since the panel and breaker #s are being field labeled at the machine or connecting junction, the NEC 408.4 (A) provisions no longer apply. PDF Electrical - Occupational Safety and Health Administration All labels and markings must be durable enough to withstand weather, chemicals, heat, corrosion, or any other environment to which they may be exposed. 4 Each Disconnect and Circuit Requires Identification 5 WORKING SPACE ABOUT ELECTRIC EQUIPMENT

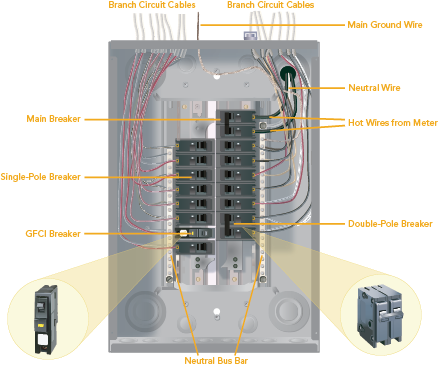

PDF Electrical Panel and Circuits, Marking - ResponsibleAg 1. The manufacturer's name, trademark or other desc riptive marking by which the organization responsible for the product may be identified; and 2. Other markings giving voltage, current, wattage or other ratings as necessary. The markings must be of sufficient durability to withstand the environment involved. Electrical Panel Label Material Requirements - Electrician Talk I have, so far, only been able to find, in both OSHA's requirements and the NFPA 70E, the following statement regarding labels: ""The marking shall be of sufficient durability to withstand the environment involved." Since we don't expect fire to exist in our substations where these labels will be used, I believe that standard plastic labels are ... If your industrial control panel is installed at the point of entry for the electrical supply circuit, the panel must be marked "Service Entrance Equipment" per the International Electrotechnical Commission (IEC) "EN Standard EN60 204-1 (2)" and NEC Art. 409. NEC + OSHA Electrical Panel Clearance Requirements In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36'' of clearance around it. Panels with 151 to 600 volts should have 42'' of clearance around it. This NEC working clearance will provide not only the person working on the equipment with room, but also their tools.

What are the Requirements for Electrical Panel Labeling? The labels that are required for electrical boxes will usually focus on two things. The first is going to be safety related labels. This could be something like a label to indicate how many volts are on a specific breaker, for example. You will also need to have the breakers labeled to indicate what area they will cut power to if turned off.

PDF NFPA 70E Labeling Requirements - ese-co.com marked labels. Panduit has a complete solution to produce field or shop printed arc flash labels including the TDP43ME printer, Easy-Mark labeling software, and printable label supplies. For more information on our solutions please visit our website. For more information on the requirement of the 2015 NFPA 70E go to the NFPA ...

NEC Changes Part I: Required on Electrical Disconnect Label All switchboards, switchgear, and panelboards supplied by a feeder (s) in other than one- or two-family dwellings shall be permanently marked to indicate each device or equipment where the power originates. The label shall be permanently affixed, of sufficient durability to withstand the environment involved, and not handwritten.

PDF Electrical Panel Requirements Very similar to CMS/NFPA requirements But with different organization & numbering Electrical Panel Requirements 22 1. Electrical Panel Requirements (Labeling, Clearances, Protection, Act) 2. Other Electrical Code Citations (Extension Cords & Power Strips, Open Boxes, Fire Stopping, Arc Flash) © 2020 LLSC Heather Lauzon Werner 23 Labeling

Nec Electrical Panel Labeling Requirements - Mike Holt ... No information is available for this page.Learn why23 pages

Electrical Code - Circuit Breaker Panel Box Requirements Some more details: Breaker panel must be at least 4 feet off the ground, but no higher than 6 feet. The panel door must be able to open at least 90 degrees. Working space around the breaker panel must be at least 30 inches wide and 72 inches from the ground up.

408.4(A) Circuit Directory or Circuit Identification. This type of general panelboard labeling will not pass final inspection using the 2014 NEC. ... code section. Once there, click on the "free access" tab and select the applicable year of NFPA 70 (National Electrical code). ... The identification shall be included in a circuit directory that is located on the face or inside of the panel door ...

Labeling an Industrial Control Panel: Tips and Tricks Wire Labeling: Establish a method and stick to it. Good practice to show where the wiring is coming from and where it is going to. Don't put too much information on the label as it can become confusing and difficult to read. Size the lables properly and don't heat shrink until testing has been completed.

What are the Requirements for Labeling Circuit Breakers? Properly labeling electrical panels is required by law by both OSHA, ANSI, and local jurisdictions. This includes marking the voltage, labeling removed ...1 answer · Top answer: When thinking about labeling circuit breakers, most people assume that the only reason to do it is to make sure you can tell what breakers go to what ...

Step by Step Guide to Labeling Your Electrical Panel — Multi Trade ... The simplest reason to label your electrical panel is that it is an Ontario Electrical Code requirement. The Electrical Safety Authority sets out a clear set of rules and policies to ensure the safety of the public. One of those rules is to have your electrical panel appropriately labeled. What you need to do this yourself

inspectapedia.com › electric › PushmaticPushmatic Bulldog & ITE Pushmatic Circuit Breakers ... Siemens purchased ITE. An electrical panel bearing the Bulldog brand and found in a home in North America today probably dates from the 1950's through the 1960's, though indeed the product label was produced as early as the mid 1930's. Pushmatic Bulldog Circuit Breaker & Electrical Panel Possible Safety & Operating Concerns

Post a Comment for "38 electrical panel label requirements"